Hello, everyone, welcome to “Inconvenient Truths”. I am your host Jennifer Zeng.

Several days ago, on Feb 20, we heard about another Boeing incident: the engine of a Boeing 777 blew apart after takeoff from Denver. It was lucky that on one was hurt. Then, two days later, on Feb 22, a Boeing 757-200 of Delta Air Lines made an emergency landing at Salt Lake International Airport after an engine performance issue.

You may also remember that in 2018 and 2019, two Boeing 737 Max crashed and killed 346 people, and that model of Boeing planes have been grounded ever since. Although the U.S. Federal Aviation Administration, FAA, announced in Nov last year that it had cleared Boeing’s 737 Max for flight after a “comprehensive and methodical məˈθɒd ɪ kəl ” 20-month review process, the planes won’t return to the skies before pilot training is done.

Have you ever asked what’s wrong with Boeing? Well, I have. Back in 2019, I did an interview on behalf of the Epoch Times with a former supply chain manager of the contractor for Boeing’s flight control systems after the crashes of the 2 Boeing 737 Max. Let’s show Picture A. This is the report I wrote after the interview. This manager told me some shocking facts: substandard parts made in China with non-aerospace material had been installed in Boeing 777 and 737 planes that are still in service !

Today I think it’s high time that I share with everyone the content of my interview again, as the problems could still exist, and haven’t been properly dealt with. If we don’t get to the bottom of the problems, more accidents could happen in the future.

Charles Shi: A Whistleblower and a Former Supply Chain Manager for Moog

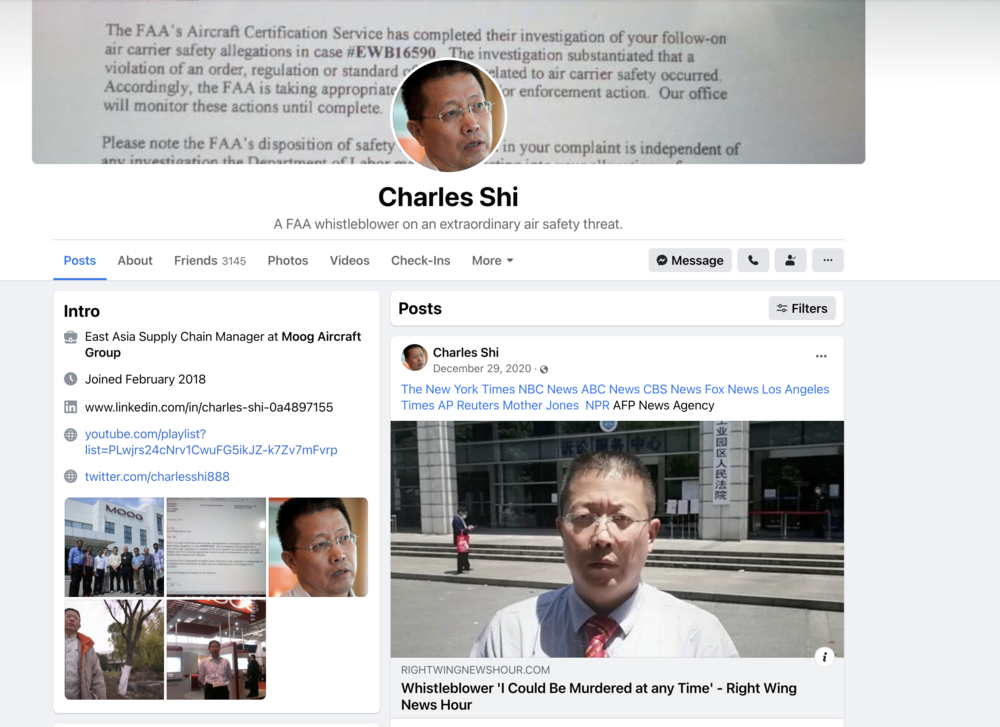

First, let’s see a few pictures of this former supply chain manager I interviewed. His English name is Charles Shi. His Chinese name is Shi Chaosheng. He worked for one of Boeing’s main suppliers, Moog Aircraft, for 10 years, from 2006 to 2016. Let’s show Picture 1, it’s a screenshot of Moog’s website. Actually, it was Charles Shi who set up the Moog supply chain in China in 2006, and almost all Moog’s suppliers inside China were audited and approved by him.

Let’s show Picture 2 now. This is Charles Shi attending the 2011 Conference of Commercial Aircraft Corporation of China in Shanghai, as both the East Asian Supply Chain Manager and C919 Program Manager for Moog.

Charles Shi attending the 2011 Conference of Commercial Aircraft Corporation of China, Ltd. (COMAC) in Shanghai, as both the East Asian Supply Chain Manager and C919 Program Manager for Moog. (Courtesy Charles Shi)

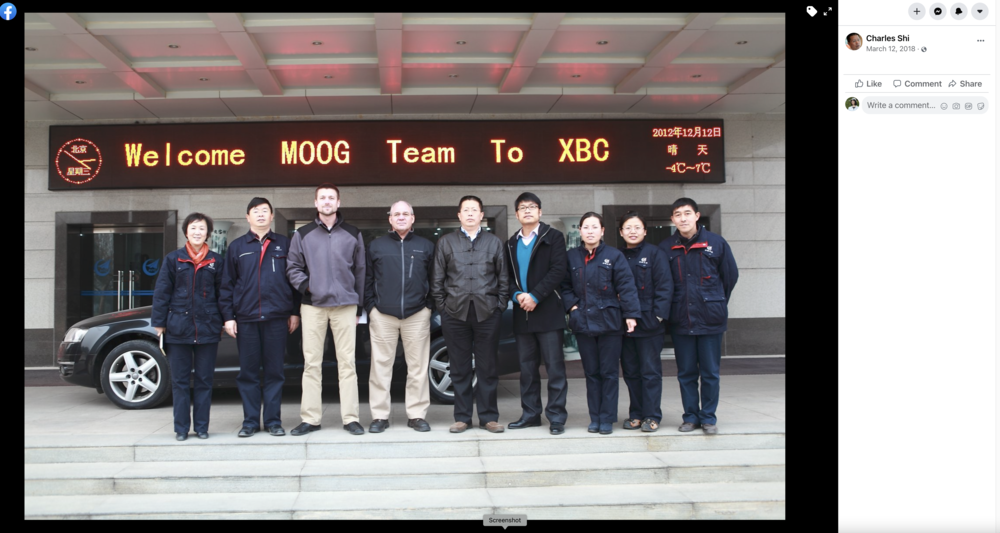

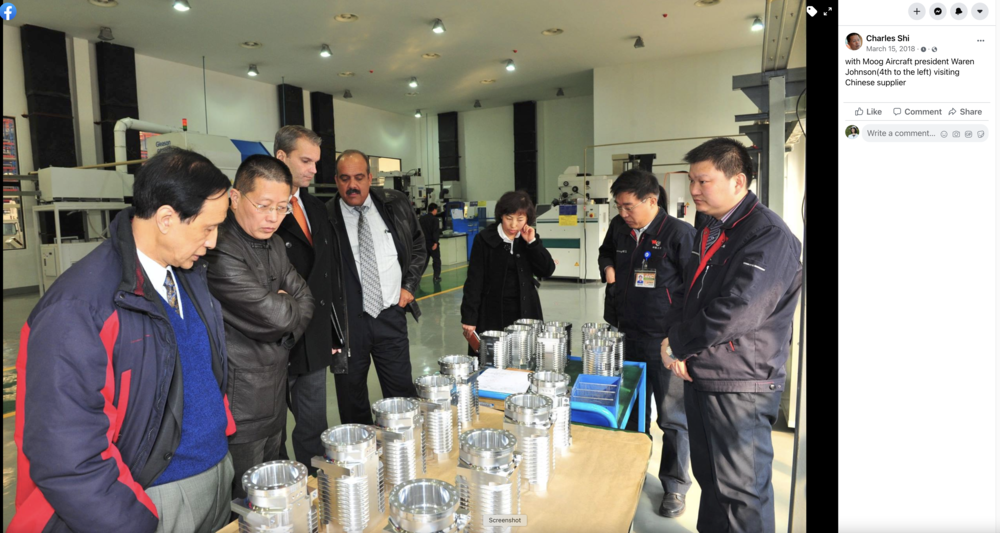

Let’s also show Picture 3, 4 and 5. These are all Charles Shi working as a manager for Moog, either attending meetings, or inspecting Chinese suppliers. These photos are from Charles’s own Facebook page. Let’s show Picture 6. This is his Facebook page.

Now, let’s watch a short video of Charles’ own introduction of what he did at Moog. I interviewed him on March 19, 2019 via Zoom. So the video you are going to see was recorded on that day.

New HongJi (NHJ) Outsources Its Orders And Fakes Material Certificates

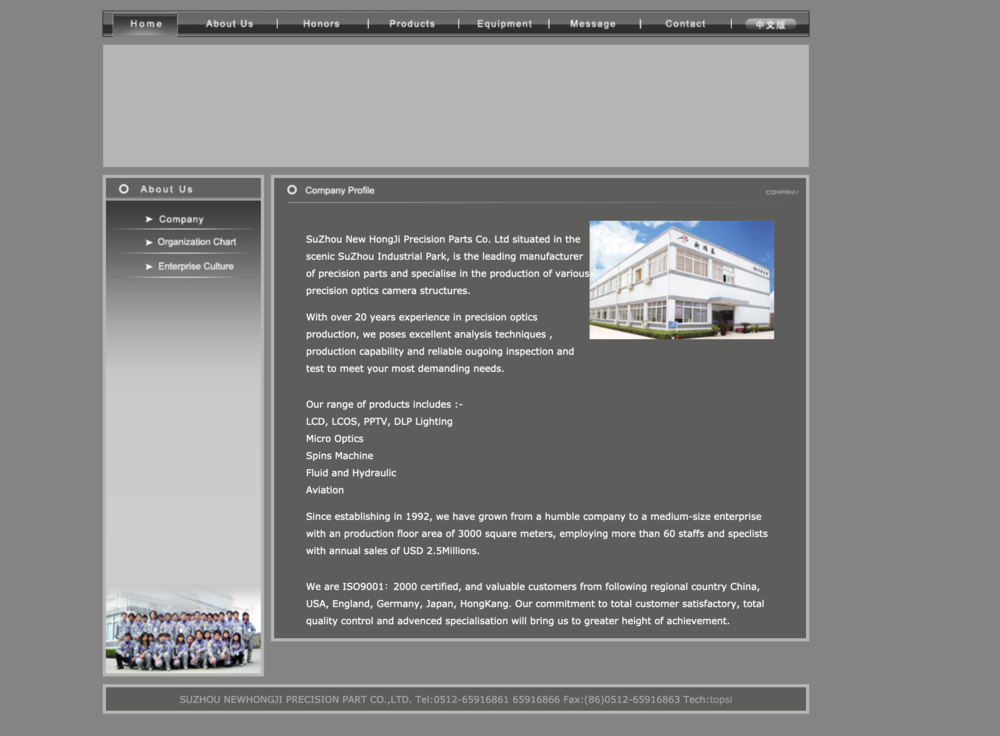

Charles told me that in 2015, he was told that one of Moog’s suppliers, New HongJi Precision Parts Co in Suzhou city, China, used substandard materials to make parts for Boeing. Let’s Show Picture 7. This is a screenshot from New Hongji’s website. You can see on its website “Aviation” products are included in what they produce. New HongJi is also called NHJ for short.

New HongJi’s website

Now, let’s listen to what Charles said about New HongJi.

The B/E Aerospace Charles mentioned is the sole source for lavatories on Boeing 737 aircrafts built since 2012, and is also the only other aerospace customer of New HongJi. Let’s show Picture 8. It is the “product” page of B/E Aerospace to show what kind of products they make.

B/E Aerospace ‘s product page

So basically Charles was saying that this B/E Aerospace had stopped buying from New HongJi after they found New HongJi used substandard materials to create parts for them. So Charles reported this issue to his supervisor at Moog and also started his own investigations about New HongJi.

Let’s watch another clip of what he says.

So basically Charles said that New HongJi outsourced ⅓ of its products to unknown, and uncertified suppliers.

Another alarming finding was that New HongJi was not adopting the proper tracing system for its materials. Let’s listen to what Charles says about this.

Charles said he later found out that New HongJi bought a small amount of qualified materials, say, 20 kgs of the material, from an approved vendor, and obtained the certificates for the materials. Then they made fake certificates for a large amount, say, 80 kgs of the materials bought from unapproved vendors to reduce the cost, because materials from unapproved vendors were much, much cheaper. Let’s watch a short clip again.

There were other issues that Charles and his managers found about New JongJi, such as their materials were not properly labeled or stored, things were very messy at their sites, etc.

So, after Charles found out all those alarming things about New HongJi, he reported them to Moog on Jan. 12, 2016. But unfortunately, he was fired on the following day.

FAA Finds Two of Charles’ Allegations “Substantiated”

He then immediately made a formal complaint to the U.S. Federal Aviation Administration, FAA, which found that two of his allegations were “substantiated”.

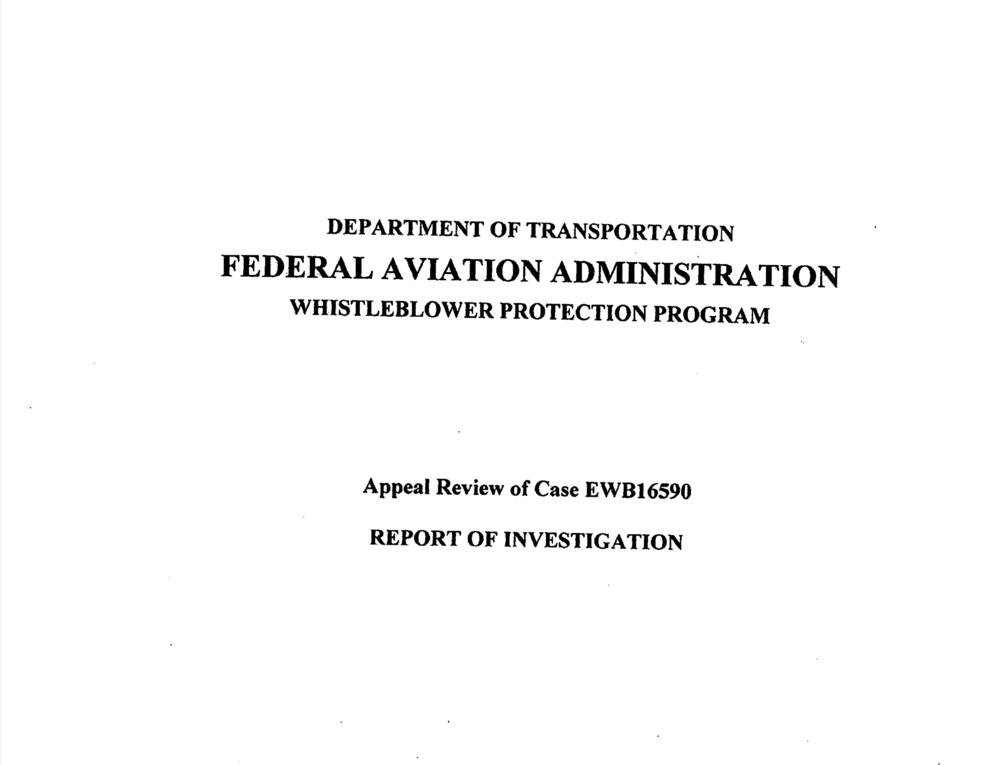

Let’s show Picture 9. It is the appeal review report issued by the FAA, which was obtained through a Freedom of Information Act request. It recorded all the complaints Charles made, and the FAA’s investigation activities, findings and follow up actions.

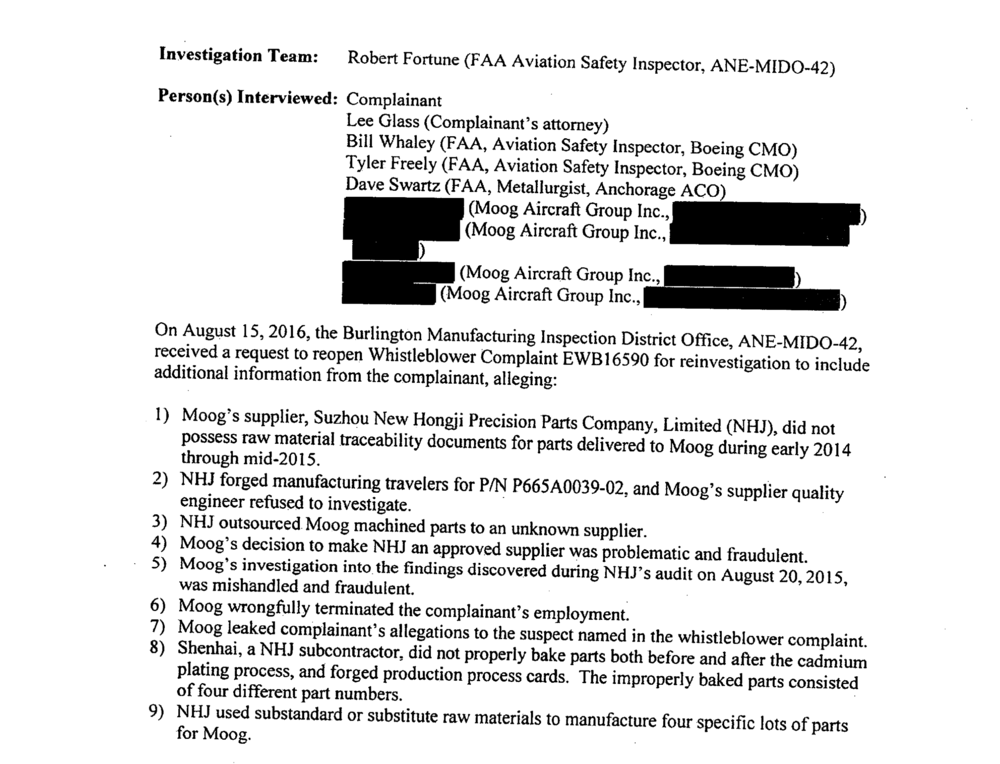

Let’s show Picture 10. We can see that Charles has made 9 complaints. I won’t read them all here. If you are interested, you can pause the video and read all the items on the screen.

P10: 9 complainants made by Charles Shi

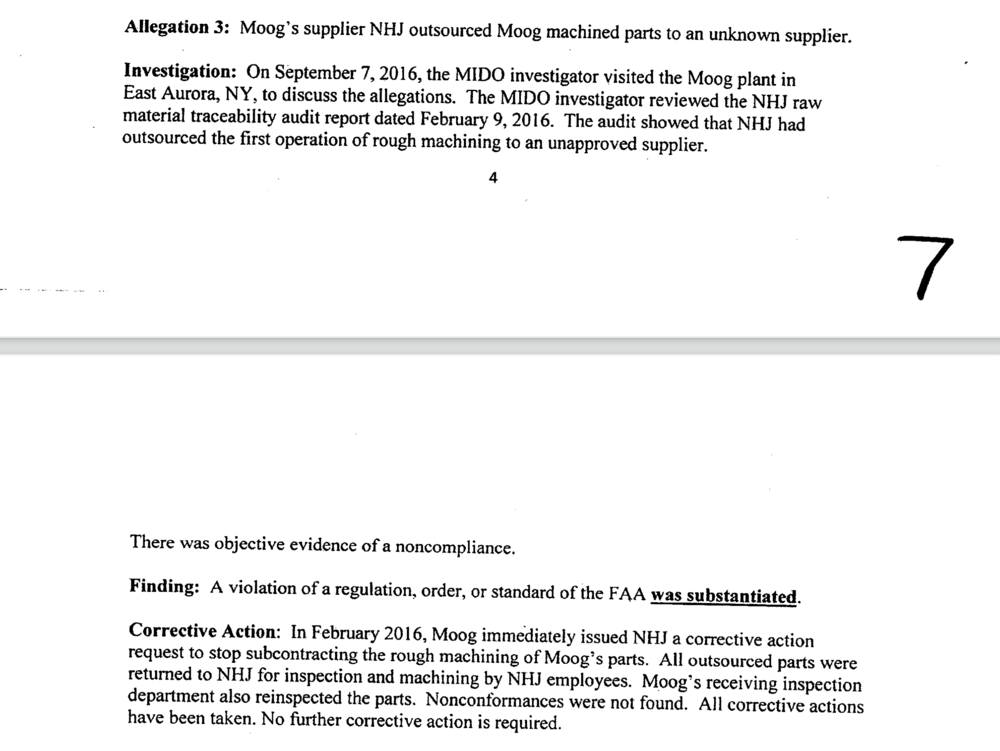

Anyway, out of the 9 items, the FAA found two allegations were “substantiated”. Let’s show Picture 11.

You can see on the screen that “Allegation 3” is: “Moog’s supplier NHJ outsourced Moog machined parts to an unknown supplier.”

And the “Finding” is: “A violation of a regulation, order, or standard of the FAA was substantiated”.

And the “corrective action” by the FAA is: “In February 2016, Moog immediately issued NHJ a corrective action request to stop subcontracting the rough machining of Moog’s parts. All outsourced parts were returned to NHJ for inspection and machining by NHJ employees. Moog’s receiving inspection department also reinspected the parts. Nonconformances were not found. All corrective actions have been taken. No further corrective action is required.”

P11: Allegation 3

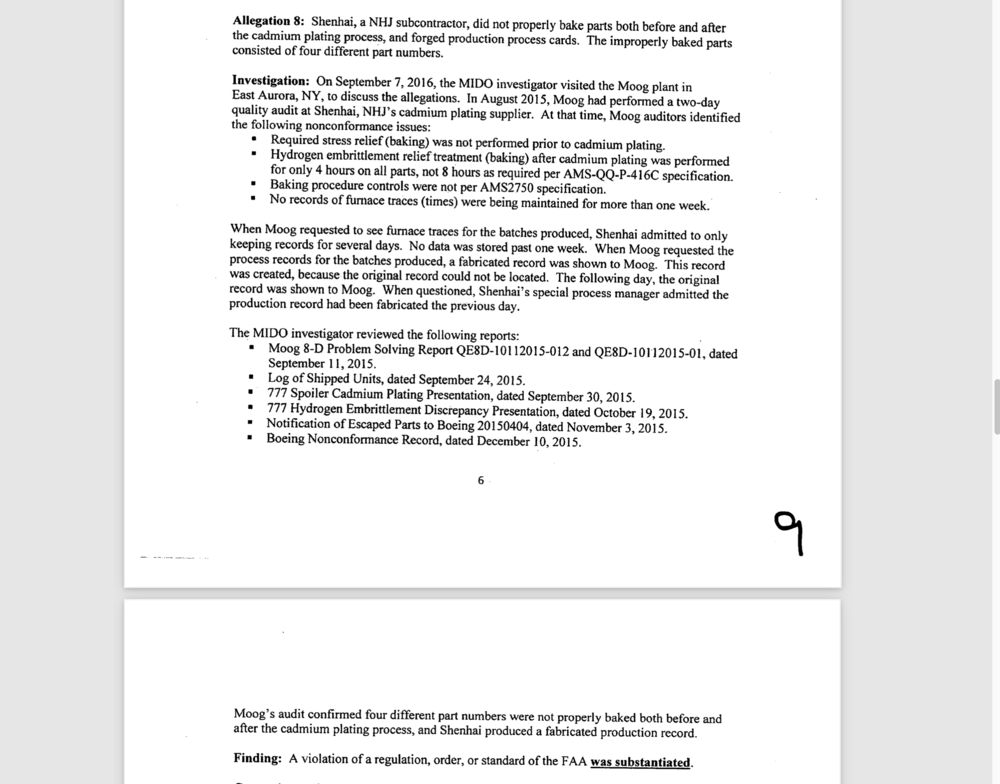

Now let’s show Picture 12. We can see that “Allegation 8” is: “Shenhai, a NHJ subcontractor, did not properly bake parts both before and after the cadmium plating process, and forged production process cards. The improperly baked parts consisted of four different part numbers.”

The FAA found following nonconformance issues:

“(a) Required stress relief (baking) was not performed prior to cadmium plating;

“(b) Hydrogen embrittlement relief treatment (baking) after cadmium plating was performed for only 4 hours on all parts, not 8 hours as required per AMS-QQ-P-416C specification;

“(c) Baking procedure controls were not per AMS2750 specification; and

“(d) No records of furnace traces [times] were being maintained for more than one week.”

And the “Finding” is: “A violation of a regulation, order, or standard of the FAA was substantiated”.

P12

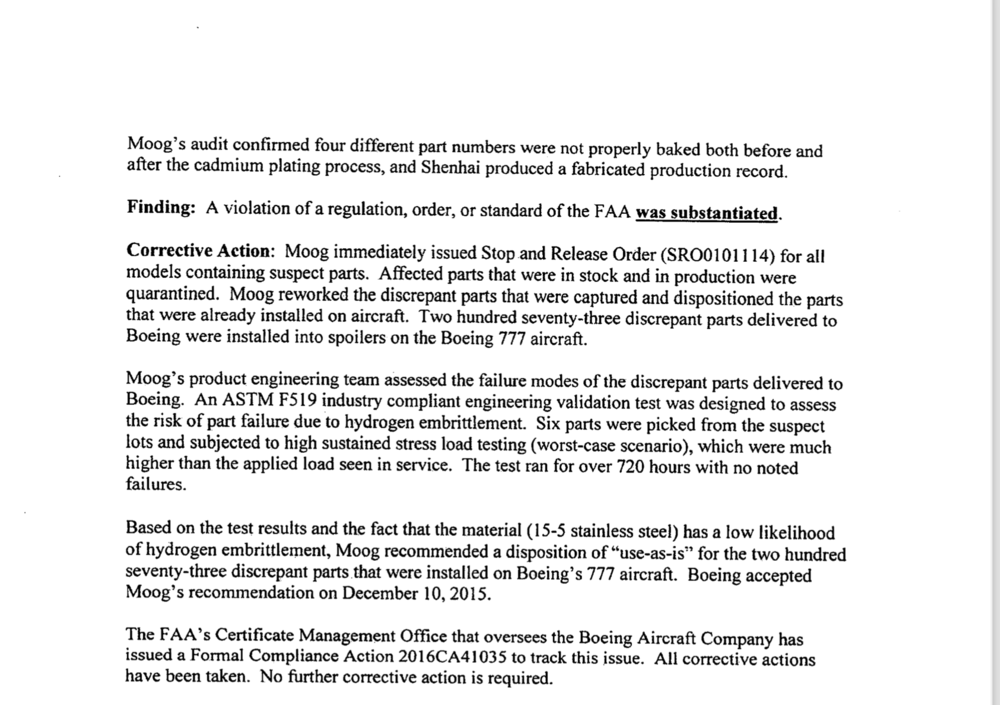

And the “corrective action” is-Let’s show Picture 13- You can see on the screen that the “corrective action” is: “Moog immediately issued Stop and Release Order for all models containing suspect parts. Affected parts that were in stock and in production were quarantined. Moog reworked the discrepant parts that were captured and dispositioned the parts that were already installed on aircraft. Two hundred seventy-three discrepant parts delivered to Boeing were installed into spoilers on the Boeing 777 aircraft.”

I will skip reading one paragraph here. Again, you can replay this part to check it out later if you are interested.

So the “corrective action” section continues to say that “Based on the test results and the fact that the material(15-5 stainless steel) has a low likelihood of hydrogen embrittlement, Moog recommended a disposition of ‘use-as-is’ for the 273 discrepant parts that were installed on Boeing’s 777 aircraft. Boeing accepted Moog’s recommendation on December 10, 2015.

“The FAA’s Certificate Management Office that oversees the Boeing Aircraft Company has issued a Formal Compliance Action 2016CA41035 to track this issue. All corrective actions have been taken. No further corrective action is required.”

By the way, I think the FAA has made a mistake with the date of when Boeing accepted Moog’s recommendation. It should be 2016 instead of 2015, as the complaint and investigation were made in 2016. So the “corrective action” couldn’t be done in 2015.

P13

Are FAA’s Follow Up Actions Good Enough?

I don’t know what you think after reading the FAA report. My thoughts are:

-

At least two allegations of Charles Shi were supported by the FAA investigations.

-

I feel very worried about how many substandard parts had already been installed on Boeing planes before New HongJi was caught and found to have outsourced their orders. When did they start doing it? Why didn’t the FAA ask Moog or Boeing to call back all the planes that already had those parts on them? Wouldn’t it be too risky?

-

After reading through the 18 page report of the FAA, I found that the FAA’s investigation team only went to Moog’s New York plant to conduct their investigation, and only listened to what Moog’s staff had to say. They didn’t send people to China, to New HongJi’s factory, to do the investigation, nor did they interview Charles Shi, the whistleblower. If you investigate a crime, and you only listen to what the suspect says, not the victim or the whistleblower says, is that investigation comprehensive and reliable? I doubt it very much.

Charles had expressed many times that if he was given the chance, he was willing to travel to the US on his own expenses to testify under oath about what he knew. But he was never given the chance.

Charles said he was not satisfied with the FAA’s handling of the matter, especially the substantiated allegations. He found himself “to be in disbelief that the FAA decided to let these admittedly unauthorized and literally unbaked parts to remain in service, sparing Moog and/or Boeing millions of dollars for removal and retrofitting.”

In response to my request for information and comment regarding Charles Shi’s allegations, the FAA emailed the following statement:

“The FAA closed its Moog investigation regarding Mr. Shi’s allegations. The agency determined the corrective action defined by Moog and Boeing associated with the open substantiated allegation was appropriate to address the related issues identified in the investigation. The FAA investigation determined unsafe conditions did not exist.”

Boeing hasn’t responded to requests for comment.

6986 Substandard “Single Point Of Failure” Parts Installed on Boeing

One of the greatest concerns of Charles is that many New HongJi parts are “safety sensitive,” and one is “safety critical.”

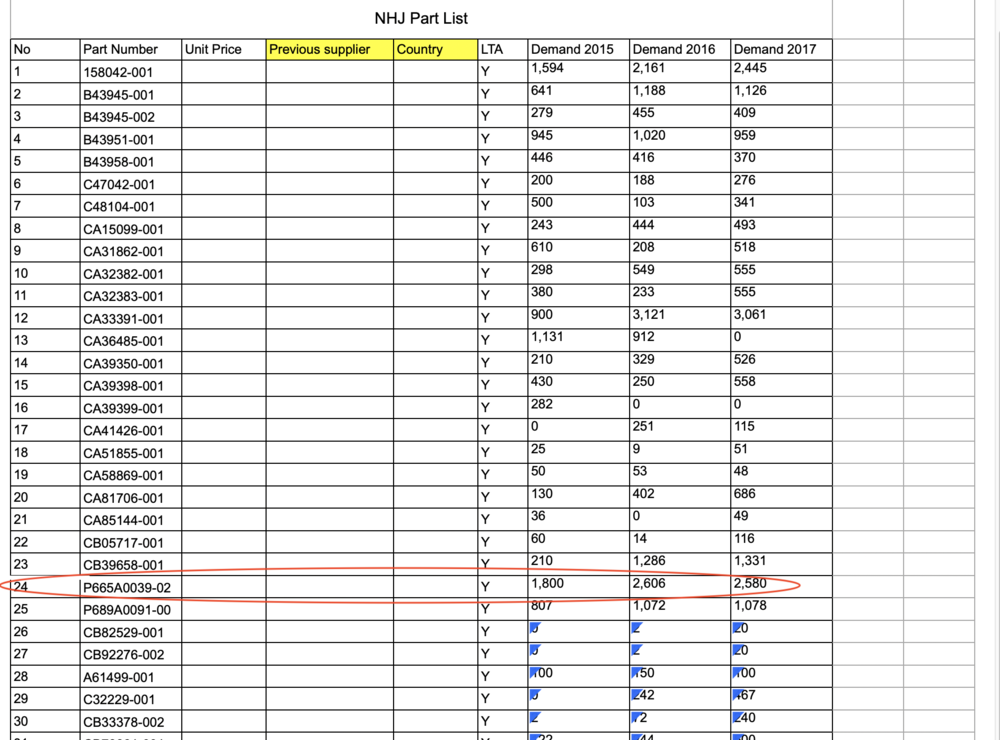

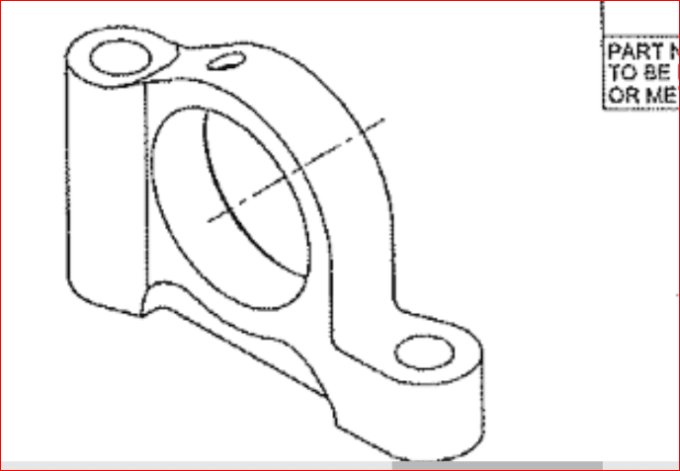

Now let’s show Picture 14. This is a purchase list provided by Charles. Please take a look at item 24 in the red circle. The Part number is P665A0039–02. This is the blocking or mounting lug of the Boeing 737’s spoiler. Let’s show Picture 15. So this is how this part looks. It is a “Single Point Of Failure (SPOF)” part; which means, if this part fails, the entire system will fail, which may cause a fatal accident.

P14

Now let’s go back to Picture 14, and look at item 24 again in the red circle. It shows that in 2015, Moog bought 1800 of this part from NHJ, 2606 in 2016, and 2580 in 2017. So altogether, Moog had bought 6986 pieces of this “Single Point Of Failure” part from NHJ in three years, from 2015 to 2017.

Charles told me that Moog is the exclusive supplier for all models of the Boeing 737, including the Max planes, and NHJ is the only supplier for this “Single Point Of Failure” part for the Boing 737 spoiler. His conservative estimate is that 500 Boeing planes may have been compromised, and are still in service.

I contacted Moog for comment back in 2019 after I interviewed Charles. Moog gave me a one-sentence statement and denied Charles’s allegations. This one-sentence statement goes like this: “In response to your request, please note that the Moog parts Mr. Shi references are not on the 737 MAX.”

I submitted a follow-up inquiry to Moog, with a list of 58 different NHJ parts purchased by Moog, and asked Moog to clarify and verify on which planes these parts are used.

But Moog did not respond to my follow-up inquiry.

Charles also told me that the substitute material was one-third or even one-half cheaper, and that was the reason why NHJ used them.

I tried to reach out to NHJ for comments too, but didn’t get a response.

A Possible Scenario of Boeing 737 Max’s Crash

Charles also demonstrated to me what he believed could be a possible scenario of Boeing 737 Max’s crash.

So, his point was, through that kind of fierce struggle by the pilot to try to take control of the airplane, if any parts of the plane were not strong enough, and couldn’t handle the pressure, it could lead to a crash.

As I am not an expert of this, I cannot make judgement on whether what Charles said was correct. However, common sense tells us that it is vitally important to make sure that every single part of the planes is made of qualified materials, not substandard ones.

P15

The Price of Being a Whistleblower

The follow up story is, after talking publicly about these problems, Charles Shi was summoned to the local police station many times. The first time when he was notified by the CCP police that he needed to go to the police station, he was so scared that he sent me a list of emergency contact numbers, and asked me to notify those people on the list if he didn’t contact me after more than 24 hours.

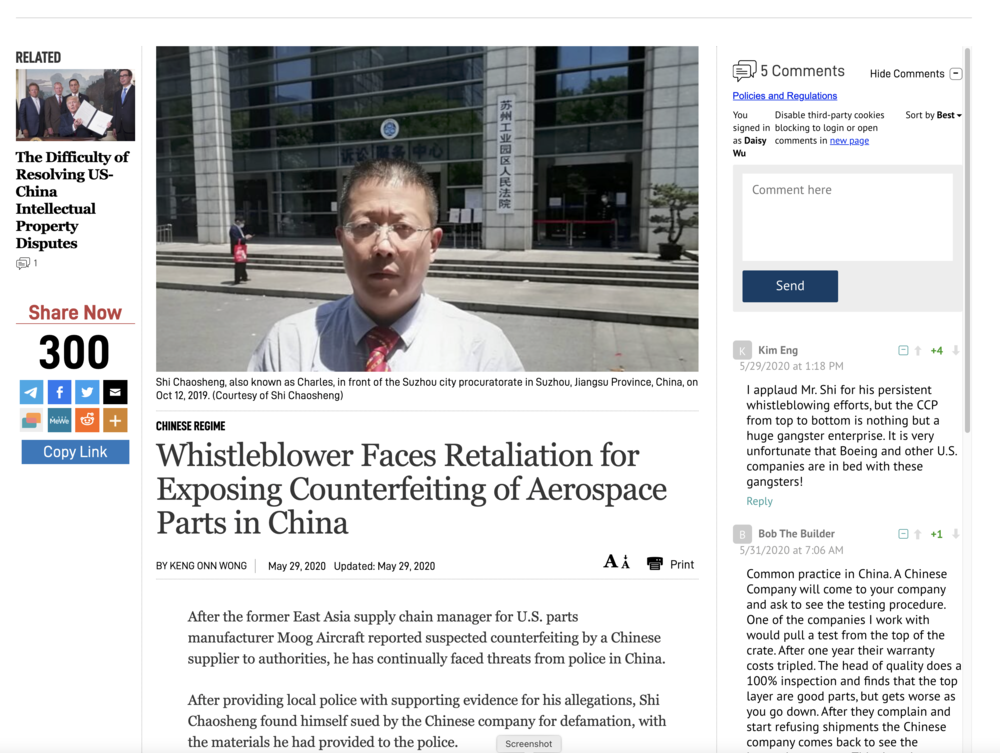

About one year later, on May 29 of last year, the Epoch Times did a follow-up story of Charles. Let’s show Picture 16. This is the follow-up story. According to this report, Charles told The Epoch Times that he was invited to a U.S. airline safety hearing on October 17, 2019, but was informed by the police that he was banned from overseas travel. The police also warned him to stop speaking to the press.

Charles also said that the CCP police told him that “NHJ counterfeiting was not necessarily a crime.”

P16

Now let’s show Picture 17. It’s a screenshot of a court ruling by the People’s Court at Suzhou Industrial Park in China. According to this ruling, Charles was sued by New HongJi in April 2019 for defamation. That was one month after he received my interview.

The court issued its judgement one year later, on April 30, 2020, and ruled that:

-

Charles must stop “infringement” on New HongJi within 10 days, and remove all his remarks and videos about New HongJi from the Internet.

-

Charles must apologize to New HongJi within 10 days, eliminate the bad impact, and restore the reputation of New HongJi.

-

Charles must pay 10,000 yuan to New Hongji within 10 days as compensation.

P17: Court ruling of the People’s Court at Suzhou Industrial Park in China

Well, that’s the price Charles had to pay for exposing the problems of New Hongji, one of Boeing’s part suppliers.

In August 2019, Charles also had to divorce his wife of 30 years, to spare her the psychological and mental stress they were going through.

Charles posted his last Facebook post on Dec 29 last year. Let’s show picture 6 again. His twitter account was suspended. Let’s show Picture 18. It is not clear when it was suspended. He used to tweet about his allegations on Twitter too.

P18: Charles Shi’s Twitter account was suspended

Well, that is the exclusive story I feel like sharing with everyone now. Haven’t I always said that “Truth saves lives”? Unfortunately, although people like Charles Shi paid such a huge price to tell a little bit of the truth, his words were not paid much attention, his efforts haven’t paid off, and the serious safety risks he worries so much about still exist.

So, if you want to help with saving lives, please do help me spread this video. Hopefully someday, somehow, before the next tragedy happens, some people will listen, pay attention, and do something about it.

That’s all for today. Please don’t forget to subscribe to my channel if you haven’t. Please also take some time to check out my other videos, like them and leave us some comments.

Thank you. See you next time!

2/24/2021

Truth Saves Lives. Subscribe and support! 真相能救命。請支持!

Donate to me directly 直接捐款:https://donorbox.org/inconvenient-truths-by-jennifer-zeng

Subscribestar 會員頻道: https://bit.ly/3fEzeJB

YouTube 油管:bit.ly/3b87DPj

GoFundme 衆籌:https://bit.ly/2zx6LVw

Patreon 網站:https://bit.ly/3cvBy3H

Paypal 捐款:http://paypal.me/JenniferZeng97

Bitcoin 捐款:bc1qlkkvwyvw96x3xx6jgzkhlnnv0nv3d9vm078vfd

Exclusive Interview: What’s Wrong with Boeing? Some Parts Are Made in China with Substandard Materials

Hello, everyone, welcome to “Inconvenient Truths”. I am your host Jennifer Zeng.

Several days ago, on Feb 20, we heard about another Boeing incident: the engine of a Boeing 777 blew apart after takeoff from Denver. It was lucky that on one was hurt. Then, two days later, on Feb 22, a Boeing 757-200 of Delta Air Lines made an emergency landing at Salt Lake International Airport after an engine performance issue.

You may also remember that in 2018 and 2019, two Boeing 737 Max crashed and killed 346 people, and that model of Boeing planes have been grounded ever since. Although the U.S. Federal Aviation Administration, FAA, announced in Nov last year that it had cleared Boeing’s 737 Max for flight after a “comprehensive and methodical məˈθɒd ɪ kəl ” 20-month review process, the planes won’t return to the skies before pilot training is done.

Have you ever asked what’s wrong with Boeing? Well, I have. Back in 2019, I did an interview on behalf of the Epoch Times with a former supply chain manager of the contractor for Boeing’s flight control systems after the crashes of the 2 Boeing 737 Max. Let’s show Picture A. This is the report I wrote after the interview. This manager told me some shocking facts: substandard parts made in China with non-aerospace material had been installed in Boeing 777 and 737 planes that are still in service !

Today I think it’s high time that I share with everyone the content of my interview again, as the problems could still exist, and haven’t been properly dealt with. If we don’t get to the bottom of the problems, more accidents could happen in the future.

Charles Shi: A Whistleblower and a Former Supply Chain Manager for Moog

First, let’s see a few pictures of this former supply chain manager I interviewed. His English name is Charles Shi. His Chinese name is Shi Chaosheng. He worked for one of Boeing’s main suppliers, Moog Aircraft, for 10 years, from 2006 to 2016. Let’s show Picture 1, it’s a screenshot of Moog’s website. Actually, it was Charles Shi who set up the Moog supply chain in China in 2006, and almost all Moog’s suppliers inside China were audited and approved by him.

Let’s show Picture 2 now. This is Charles Shi attending the 2011 Conference of Commercial Aircraft Corporation of China in Shanghai, as both the East Asian Supply Chain Manager and C919 Program Manager for Moog.

Charles Shi attending the 2011 Conference of Commercial Aircraft Corporation of China, Ltd. (COMAC) in Shanghai, as both the East Asian Supply Chain Manager and C919 Program Manager for Moog. (Courtesy Charles Shi)

Let’s also show Picture 3, 4 and 5. These are all Charles Shi working as a manager for Moog, either attending meetings, or inspecting Chinese suppliers. These photos are from Charles’s own Facebook page. Let’s show Picture 6. This is his Facebook page.

Now, let’s watch a short video of Charles’ own introduction of what he did at Moog. I interviewed him on March 19, 2019 via Zoom. So the video you are going to see was recorded on that day.

New HongJi (NHJ) Outsources Its Orders And Fakes Material Certificates

Charles told me that in 2015, he was told that one of Moog’s suppliers, New HongJi Precision Parts Co in Suzhou city, China, used substandard materials to make parts for Boeing. Let’s Show Picture 7. This is a screenshot from New Hongji’s website. You can see on its website “Aviation” products are included in what they produce. New HongJi is also called NHJ for short.

New HongJi’s website

Now, let’s listen to what Charles said about New HongJi.

The B/E Aerospace Charles mentioned is the sole source for lavatories on Boeing 737 aircrafts built since 2012, and is also the only other aerospace customer of New HongJi. Let’s show Picture 8. It is the “product” page of B/E Aerospace to show what kind of products they make.

B/E Aerospace ‘s product page

So basically Charles was saying that this B/E Aerospace had stopped buying from New HongJi after they found New HongJi used substandard materials to create parts for them. So Charles reported this issue to his supervisor at Moog and also started his own investigations about New HongJi.

Let’s watch another clip of what he says.

So basically Charles said that New HongJi outsourced ⅓ of its products to unknown, and uncertified suppliers.

Another alarming finding was that New HongJi was not adopting the proper tracing system for its materials. Let’s listen to what Charles says about this.

Charles said he later found out that New HongJi bought a small amount of qualified materials, say, 20 kgs of the material, from an approved vendor, and obtained the certificates for the materials. Then they made fake certificates for a large amount, say, 80 kgs of the materials bought from unapproved vendors to reduce the cost, because materials from unapproved vendors were much, much cheaper. Let’s watch a short clip again.

There were other issues that Charles and his managers found about New JongJi, such as their materials were not properly labeled or stored, things were very messy at their sites, etc.

So, after Charles found out all those alarming things about New HongJi, he reported them to Moog on Jan. 12, 2016. But unfortunately, he was fired on the following day.

FAA Finds Two of Charles’ Allegations “Substantiated”

He then immediately made a formal complaint to the U.S. Federal Aviation Administration, FAA, which found that two of his allegations were “substantiated”.

Let’s show Picture 9. It is the appeal review report issued by the FAA, which was obtained through a Freedom of Information Act request. It recorded all the complaints Charles made, and the FAA’s investigation activities, findings and follow up actions.

Let’s show Picture 10. We can see that Charles has made 9 complaints. I won’t read them all here. If you are interested, you can pause the video and read all the items on the screen.

P10: 9 complainants made by Charles Shi

Anyway, out of the 9 items, the FAA found two allegations were “substantiated”. Let’s show Picture 11.

You can see on the screen that “Allegation 3” is: “Moog’s supplier NHJ outsourced Moog machined parts to an unknown supplier.”

And the “Finding” is: “A violation of a regulation, order, or standard of the FAA was substantiated”.

And the “corrective action” by the FAA is: “In February 2016, Moog immediately issued NHJ a corrective action request to stop subcontracting the rough machining of Moog’s parts. All outsourced parts were returned to NHJ for inspection and machining by NHJ employees. Moog’s receiving inspection department also reinspected the parts. Nonconformances were not found. All corrective actions have been taken. No further corrective action is required.”

P11: Allegation 3

Now let’s show Picture 12. We can see that “Allegation 8” is: “Shenhai, a NHJ subcontractor, did not properly bake parts both before and after the cadmium plating process, and forged production process cards. The improperly baked parts consisted of four different part numbers.”

The FAA found following nonconformance issues:

“(a) Required stress relief (baking) was not performed prior to cadmium plating;

“(b) Hydrogen embrittlement relief treatment (baking) after cadmium plating was performed for only 4 hours on all parts, not 8 hours as required per AMS-QQ-P-416C specification;

“(c) Baking procedure controls were not per AMS2750 specification; and

“(d) No records of furnace traces [times] were being maintained for more than one week.”

And the “Finding” is: “A violation of a regulation, order, or standard of the FAA was substantiated”.

P12

And the “corrective action” is-Let’s show Picture 13- You can see on the screen that the “corrective action” is: “Moog immediately issued Stop and Release Order for all models containing suspect parts. Affected parts that were in stock and in production were quarantined. Moog reworked the discrepant parts that were captured and dispositioned the parts that were already installed on aircraft. Two hundred seventy-three discrepant parts delivered to Boeing were installed into spoilers on the Boeing 777 aircraft.”

I will skip reading one paragraph here. Again, you can replay this part to check it out later if you are interested.

So the “corrective action” section continues to say that “Based on the test results and the fact that the material(15-5 stainless steel) has a low likelihood of hydrogen embrittlement, Moog recommended a disposition of ‘use-as-is’ for the 273 discrepant parts that were installed on Boeing’s 777 aircraft. Boeing accepted Moog’s recommendation on December 10, 2015.

“The FAA’s Certificate Management Office that oversees the Boeing Aircraft Company has issued a Formal Compliance Action 2016CA41035 to track this issue. All corrective actions have been taken. No further corrective action is required.”

By the way, I think the FAA has made a mistake with the date of when Boeing accepted Moog’s recommendation. It should be 2016 instead of 2015, as the complaint and investigation were made in 2016. So the “corrective action” couldn’t be done in 2015.

P13

Are FAA’s Follow Up Actions Good Enough?

I don’t know what you think after reading the FAA report. My thoughts are:

At least two allegations of Charles Shi were supported by the FAA investigations.

I feel very worried about how many substandard parts had already been installed on Boeing planes before New HongJi was caught and found to have outsourced their orders. When did they start doing it? Why didn’t the FAA ask Moog or Boeing to call back all the planes that already had those parts on them? Wouldn’t it be too risky?

After reading through the 18 page report of the FAA, I found that the FAA’s investigation team only went to Moog’s New York plant to conduct their investigation, and only listened to what Moog’s staff had to say. They didn’t send people to China, to New HongJi’s factory, to do the investigation, nor did they interview Charles Shi, the whistleblower. If you investigate a crime, and you only listen to what the suspect says, not the victim or the whistleblower says, is that investigation comprehensive and reliable? I doubt it very much.

Charles had expressed many times that if he was given the chance, he was willing to travel to the US on his own expenses to testify under oath about what he knew. But he was never given the chance.

Charles said he was not satisfied with the FAA’s handling of the matter, especially the substantiated allegations. He found himself “to be in disbelief that the FAA decided to let these admittedly unauthorized and literally unbaked parts to remain in service, sparing Moog and/or Boeing millions of dollars for removal and retrofitting.”

In response to my request for information and comment regarding Charles Shi’s allegations, the FAA emailed the following statement:

“The FAA closed its Moog investigation regarding Mr. Shi’s allegations. The agency determined the corrective action defined by Moog and Boeing associated with the open substantiated allegation was appropriate to address the related issues identified in the investigation. The FAA investigation determined unsafe conditions did not exist.”

Boeing hasn’t responded to requests for comment.

6986 Substandard “Single Point Of Failure” Parts Installed on Boeing

One of the greatest concerns of Charles is that many New HongJi parts are “safety sensitive,” and one is “safety critical.”

Now let’s show Picture 14. This is a purchase list provided by Charles. Please take a look at item 24 in the red circle. The Part number is P665A0039–02. This is the blocking or mounting lug of the Boeing 737’s spoiler. Let’s show Picture 15. So this is how this part looks. It is a “Single Point Of Failure (SPOF)” part; which means, if this part fails, the entire system will fail, which may cause a fatal accident.

P14

Now let’s go back to Picture 14, and look at item 24 again in the red circle. It shows that in 2015, Moog bought 1800 of this part from NHJ, 2606 in 2016, and 2580 in 2017. So altogether, Moog had bought 6986 pieces of this “Single Point Of Failure” part from NHJ in three years, from 2015 to 2017.

Charles told me that Moog is the exclusive supplier for all models of the Boeing 737, including the Max planes, and NHJ is the only supplier for this “Single Point Of Failure” part for the Boing 737 spoiler. His conservative estimate is that 500 Boeing planes may have been compromised, and are still in service.

I contacted Moog for comment back in 2019 after I interviewed Charles. Moog gave me a one-sentence statement and denied Charles’s allegations. This one-sentence statement goes like this: “In response to your request, please note that the Moog parts Mr. Shi references are not on the 737 MAX.”

I submitted a follow-up inquiry to Moog, with a list of 58 different NHJ parts purchased by Moog, and asked Moog to clarify and verify on which planes these parts are used.

But Moog did not respond to my follow-up inquiry.

Charles also told me that the substitute material was one-third or even one-half cheaper, and that was the reason why NHJ used them.

I tried to reach out to NHJ for comments too, but didn’t get a response.

A Possible Scenario of Boeing 737 Max’s Crash

Charles also demonstrated to me what he believed could be a possible scenario of Boeing 737 Max’s crash.

So, his point was, through that kind of fierce struggle by the pilot to try to take control of the airplane, if any parts of the plane were not strong enough, and couldn’t handle the pressure, it could lead to a crash.

As I am not an expert of this, I cannot make judgement on whether what Charles said was correct. However, common sense tells us that it is vitally important to make sure that every single part of the planes is made of qualified materials, not substandard ones.

P15

The Price of Being a Whistleblower

The follow up story is, after talking publicly about these problems, Charles Shi was summoned to the local police station many times. The first time when he was notified by the CCP police that he needed to go to the police station, he was so scared that he sent me a list of emergency contact numbers, and asked me to notify those people on the list if he didn’t contact me after more than 24 hours.

About one year later, on May 29 of last year, the Epoch Times did a follow-up story of Charles. Let’s show Picture 16. This is the follow-up story. According to this report, Charles told The Epoch Times that he was invited to a U.S. airline safety hearing on October 17, 2019, but was informed by the police that he was banned from overseas travel. The police also warned him to stop speaking to the press.

Charles also said that the CCP police told him that “NHJ counterfeiting was not necessarily a crime.”

P16

Now let’s show Picture 17. It’s a screenshot of a court ruling by the People’s Court at Suzhou Industrial Park in China. According to this ruling, Charles was sued by New HongJi in April 2019 for defamation. That was one month after he received my interview.

The court issued its judgement one year later, on April 30, 2020, and ruled that:

Charles must stop “infringement” on New HongJi within 10 days, and remove all his remarks and videos about New HongJi from the Internet.

Charles must apologize to New HongJi within 10 days, eliminate the bad impact, and restore the reputation of New HongJi.

Charles must pay 10,000 yuan to New Hongji within 10 days as compensation.

P17: Court ruling of the People’s Court at Suzhou Industrial Park in China

Well, that’s the price Charles had to pay for exposing the problems of New Hongji, one of Boeing’s part suppliers.

In August 2019, Charles also had to divorce his wife of 30 years, to spare her the psychological and mental stress they were going through.

Charles posted his last Facebook post on Dec 29 last year. Let’s show picture 6 again. His twitter account was suspended. Let’s show Picture 18. It is not clear when it was suspended. He used to tweet about his allegations on Twitter too.

P18: Charles Shi’s Twitter account was suspended

Well, that is the exclusive story I feel like sharing with everyone now. Haven’t I always said that “Truth saves lives”? Unfortunately, although people like Charles Shi paid such a huge price to tell a little bit of the truth, his words were not paid much attention, his efforts haven’t paid off, and the serious safety risks he worries so much about still exist.

So, if you want to help with saving lives, please do help me spread this video. Hopefully someday, somehow, before the next tragedy happens, some people will listen, pay attention, and do something about it.

That’s all for today. Please don’t forget to subscribe to my channel if you haven’t. Please also take some time to check out my other videos, like them and leave us some comments.

Thank you. See you next time!

2/24/2021

Truth Saves Lives. Subscribe and support! 真相能救命。請支持!

Donate to me directly 直接捐款:https://donorbox.org/inconvenient-truths-by-jennifer-zeng

Subscribestar 會員頻道: https://bit.ly/3fEzeJB

YouTube 油管:bit.ly/3b87DPj

GoFundme 衆籌:https://bit.ly/2zx6LVw

Patreon 網站:https://bit.ly/3cvBy3H

Paypal 捐款:http://paypal.me/JenniferZeng97

Bitcoin 捐款:bc1qlkkvwyvw96x3xx6jgzkhlnnv0nv3d9vm078vfd